With the success of the IDEAL CT testing standard, which is rapidly becoming the cracking test of choice for Balanced Mix Design, Dr. Fujie Zhou of Texas A&M University set about developing a quick test for evaluating rutting. Rutting in most HMA pavements is due to shear deformation of the HMA layer. Back in the ‘90s, the Superpave Shear Tester (SST) was developed as part of SHRP research to be one of the HMA mixture performance tests for Superpave mix design. The SST applies a repeated shear load to a specimen created in a gyratory compactor. It was not widely adopted due to its complexity and cost. However, with continuing problems with rutting, some DOTs proceeded to investigate a simple solution for rutting testing as an addition to volumetrics.

States such as Utah, Kansas and Texas were early adopters of the Hamburg wheel tracking test from Europe. This test has become extremely popular due to its ease of use and relatively low equipment cost. It is now specified in many states across the US. However, one drawback of the Hamburg test is that it takes over 6 hours to complete, which is a long time for QA/QC purposes. When the IDEAL RT test was under development, considerations were given for designing a test that focused on speed, simplicity, practicality, economics, repeatability, sensitivity to changes in mixture properties and correlation to field performance. Since repeated load tests using the Overlay or Hamburg methods take longer to perform, it was decided that monotonic loading would be used with the IDEAL RT test.

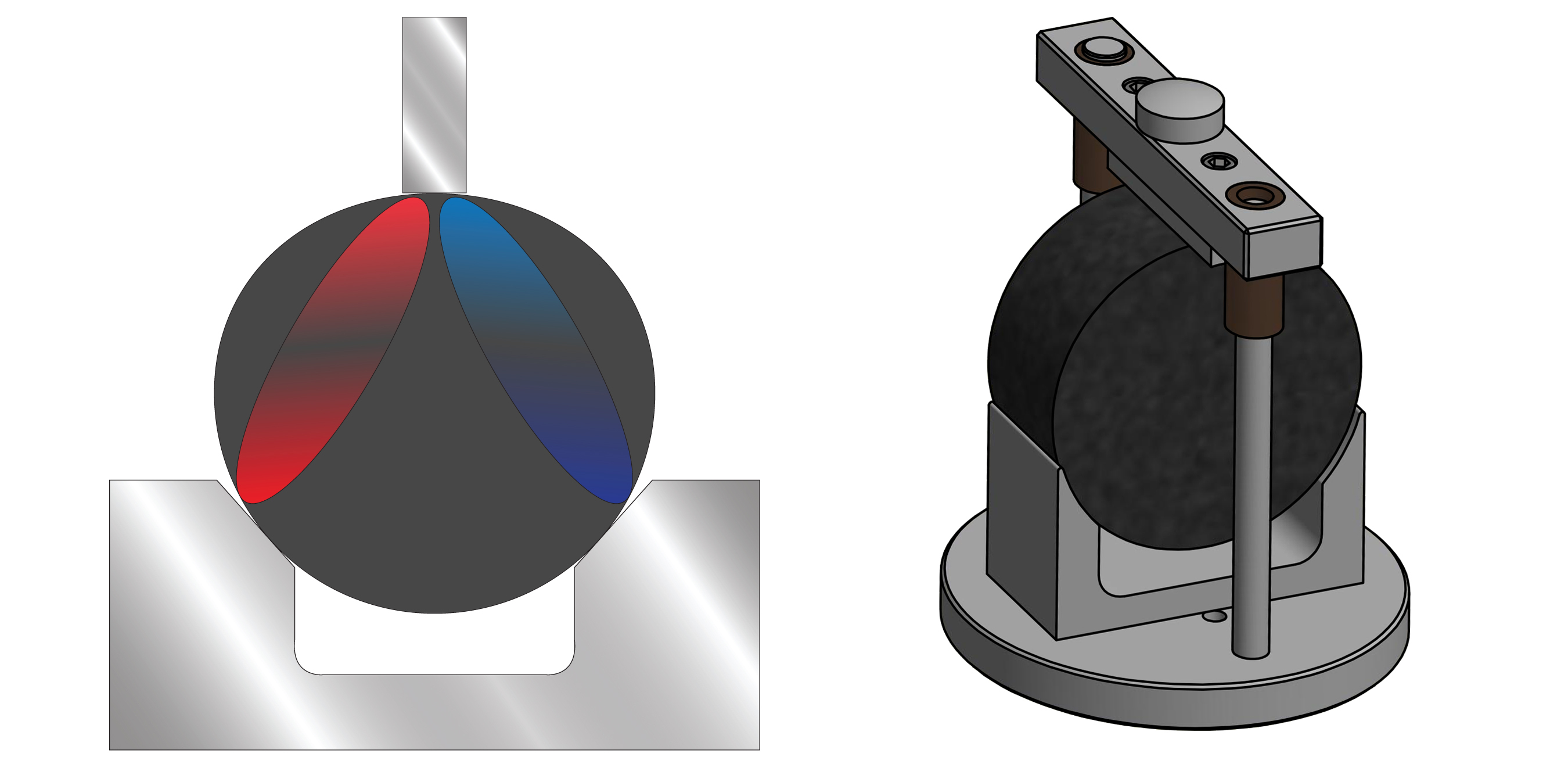

The concept of the IDEAL RT test is derived from three-point bending and SCB tests, but with two significant changes. As with IDEAL CT, a gyratory compactor specimen (150mm diameter and 62mm high) is used. But, rather than sitting on rollers, the specimen is constrained by a rigid fixture. IDEAL RT, like IDEAL CT, also uses a typical Marshall/TSR load frame to apply load to the sample. In IDEAL CT testing a dominant horizontal tensile stress is created when the load is applied to the specimen. However, in IDEAL RT testing with its rigid fixture, two, separate shear planes are developed upon the load being applied to the specimen. The IDEAL RT test is also performed at 50°C to match the Hamburg wheel tracking test in Texas. It is expected that other States are likely to match the temperature used for IDEAL RT testing with their State Hamburg temperature specification.

For IDEAL RT testing, specimen size was kept the same as the Hamburg and IDEAL CT tests to facilitate easy specimen manufacture. The same load frame used to perform IDEAL CT testing can be used to perform IDEAL RT, again to make the test simple and inexpensive. In correlation trials, IDEAL RT correlated very well with both the Hamburg and APA test. It has also performed well in field performance trials.

If you are looking for a load frame, which can perform these tests automatically, take a look at Humboldt's HM-5125 Balanced Mix Design Load Frame, click here. Humboldt‘s HM-5125.3F load frame has been designed to provide precise test rate control for the automated testing of balanced mix samples.

Tests that can be run are:

• Marshall — ASTM D6927, AASHTO T245

• TSR — AASHTO T283

• I-FIT (SCB IL Method) — AASHTO TP124

• SCB (LSU Method) — ASTM D8084

• IDEAL-CT (TTI Method) — ASTM D8225

• IDEAL-RT (TTI Method) — ASTM WK71466

• ISS (Interlayer Shear Strength) — AASHTO TP114

At the completion of each test, the HM-5125 will display test results on its display screen per current ASTM or AASHTO specifications. This function eliminates the need for operators to download or transfer data to a computer for calculating or displaying test results. This also allows operators the ability to quickly evaluate whether a specimen mix design is within desired specifications.